Having the right chefs knife for the task at hand can make food preparation easier. But with so many different types of chefs knife available on the UK market, choosing the right kind of knife can be a challenge. To help you with your buyers’ journey, we’ve put a simple guide together to help you find the right type of knife.

Written by our expert product consultants, with insight from chefs, restauranteurs and commercial kitchen managers, this independent guide talks through all the different types of knife available and takes a brief look at other aspects you should consider, such as knife quality, construction and the material used in manufacturing process.

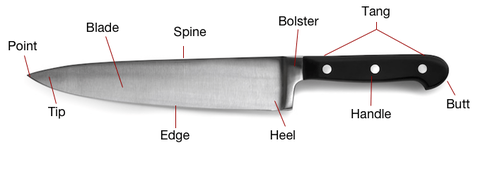

Anatomy Of Chefs Knives

| Point | The end of the blade, sharpened to a fine point, can be used to score and pierce the surface of the food. |

| Blade | This is about the part of the knife which is used for cutting, typically made from steel. |

| Edge | The sharpest part of the blade used for the majority of cutting. |

| Tip | Just below the point, this is used for delicate chopping and cutting work. |

| Spine | The blunt upper side. The thickness provides strength to the blade and contributes to the balance of the knife. |

| Handle | Used to grasp the knife. Some manufacturers will design the knife, so the tang is used as the handle. |

| Bolster | The top area between the blade and the handle. It creates a space between the user’s fingers and the blade to prevent slipping. |

| Rivets | Some knives feature rivets to fix the handle to the tang. Cheaper blades do not use rivets, using epoxy or resin instead. |

Forged vs Stamped Chefs Knives

It's important to note that the manufacturing process of stamped chefs knives has been refined so much over the last decade that there are now ranges of stamped blade that have comparable quality to their fully forged counterparts. Some chefs even prefer them thanks to their lighter weight provides higher comfort.

| Forged Chefs Knives | A forged chefs knife has been made from a single type of metal. Steel is hammered into shape using a press before being honed and sharpened. The handle is then added. When it is forged the process alters the form down to the molecular level resulting in considering strength and durability. Forge knives can be more expensive than stamped designs due to the costly time and labour crafting process. However, this means you will not need to invest in any new knives for many years as they are very long lasting. |

| Stamped Chefs Knives | Stamped chefs knives are made using a single sheet of steel which is then cut into shape to make the blade. The handle is then attached after. As they are typically constructed from a thinner sheet of steel, stamped knives are generally lighter than forged knives. This also means that the manufacturing process is a lot quicker making stamped knives much more affordable than forges ones, however, as the process is quicker and cheaper they are not as good at retaining their edge as forge knives are. |

Types of Chefs Knife

Chef's Knife: A chef’s knife has a long, broad blade with a straight edge, the blade is widest across the heel which then tapers to a fine point. The chef’s knives curvature allows for it to rock back and forth on a chopping board making it ideal for chopping and dicing lots of vegetables at once. The wide heel will enable it to stand up to more pressure allowing you to cut thicker or harder foods like onions, potatoes or parsnips.

Utility Knife: A similar shape to a chef’s knife, utility knives feature a slimmer and smaller with a sharp tip that tapers towards the spine. These knives are great for chopping smaller foods and vegetables as the utility knife allows for more precise cutting.

Paring Knife: A short and slim design, a paring knife is an evenly sized blade with a pointed tip. They tend to be lighter for easier handling during delicate work. The pairing knife is used mainly to slice chop and cut fruit and vegetables, although they can be used on harder foods like potatoes despite their smaller size but remains manoeuvrable enough to carry out tasks peeling, trimming and removing seeds from fruit and veg.

Bread Knife: Equipped with a long, evenly sized blade with a serrated edge, this type of knife is designed to be used on softer items. The sharp serrated, saw-like edge is perfect for cutting through all different kinds of bread like crusty bread, baguettes, bagels and bread rolls. The grooved side allows the user to cut through softer texture without crushing them out of shape. Bread knives can also be applied to slice cakes with soft surfaces as the knife can cut without the air being withdrawn from the sponge.

Carving Knife: A carving knife is a long slim knife the tapers to a sharp point, being one of the longest carving knives in the kitchen. Its width is narrower than other knives but produces less drag as it cuts through food, allowing It to create clean and uniform slices, this makes the carving knife perfect for meat and poultry.

Butchers Knife: Also known as a cleavers knife, this knife is used to chop up raw meat, it is mainly used in butchery establishments but is also used to divide meat into smaller portions in commercial kitchen environments. The large and heavy design of this knife means that they can even cut through bone. The broadhead can also come in handy for crushing garlic cloves against a chopping board.

Boning Knife: A boning knife has a slim blade with an extremely sharp edge which tapers typically up to a fine point. This design makes this knife an ideal choice for cutting around bone without damaging the surrounding flesh. The blade can also be used to cut through cartilage. For different types of meats, a harder boning knife is better for deboning pork and beef while a more flexible boning knife is better suited to poultry.

Filleting Knife: Similar to a boning knife, a filleting knife is a long slim knife with a flexible blade and a sharp edge as well as fine pointed tip however in comparison with a boning knife, these knives are thinner and more flexible. Filleting blades are perfect for removing bones from fish without damaging the delicate flesh. Often used to cut through horizontally rather than vertically to allows the users to cut around the backbone of the fish to create perfect fillets.

Santoku Knife: Originating from Japan, these knives are ideal for precise cutting, dicing and mincing, they have a long blade with a shallow taper as well as drop point to allow more precise intricate cutting work, normal they feature dimpling along the blade which work to prevent delicate food items from sticking to the metal surface. Santoku’s edges and drop point make it excellent for cutting fish like sushi. They also find an ease of chopping vegetables.

Tomato Knife: Designed to be lightweight and easy to handle, these knives feature a sharp serrated edge with a rounded blade. As the name suggests tomato knives are designed to slice tomatoes as the serrated edge can cut through the tomato's skin without squishing the softer interior, this allows for even slices perfect for keeping meals looking consistent.

Types of Knife Edge:

The most important part of any knife, the edge is what gives the knife is sharp cutting power but not every edge is suited to every food type.

| Straight: | The most common edge, this type of edge is found on chef’s knives, paring knives and utility knives. |

| Serrated: | This edge features sharpened grooves and ridges along the blade which helps to cut more robust foods, however. They are also useful for slicing softer foods without squishing the shape. Knives that feature this edge are bread, tomato and steak knives. |

| Scalloped: | This edge has hollow dimples along the blade to prevent the food sticking to the surface of the knife when cutting; they are typically used for cutting wet or sticky foods like raw fish or vegetables, scalloped edges feature on santoku and salmon knives. |

| Hollow Ground: | Hollow edge tapers down from the middle of the blade creating a very fine and sharp edge, however with the extreme sharpness they become vulnerable to wear and breakage and will require frequent sharpening, this edge is customarily found on Nakiri Knives. |

Blade Material:

The material used to craft the blade from can affect the levels of strength, durability and sharpness so knowing what’s the best blade material is vital, so you can achieve the results you want out of your commercial knives.

| Stainless Steel | Easily the most popular metal for knives, stainless steel offers excellent durability and resistance to corrosion and rusting; the alloy is a mix of iron as it's base metal combined with carbon which makes the blade sharp and durable, then chromium is added to prevent stains and create a shiny finish. A negative of stainless steel is that the quality can drastically change depending on the brand or supplier. At Buzz, we ensure that we only stock high-quality manufacturers. |

| Carbon Steel | Like in the way stainless steel knives are made, carbon steel knives are an alloy made from carbon and iron however chromium is not added in the process, steel with a high carbon count is used to forge knives that require high strength and rigidity, this type of steel can retain an extremely sharp edge when maintained consistently. This makes this type of steel perfect for peeling knives or butchers knife/cleavers. However, as the chromium isn’t added, they are prone to staining and discolouration. |

| Damascus Steel | This type of steel is made using combining 2 or more different alloys that hammered together creating strong steel. From this process, it creates a distinct pattern which is very aesthetically pleasing. This metal is solid, sharp and durable but Damascus steel knives come with a hefty price but despite this, they can last for years and will retain their sharp cutting edge for a long time. Damascus steel knives are ideal for serious cooks. |

| Titanium | Known as the hardest metals, titanium is nonmagnetic and has high resistant to rust. However, it tends to be less sharp and not at holding its edge, so it's less effective than stainless steel or ceramics blades. |

Maintaining Chefs Knives

Known as the hardest metals, titanium is nonmagnetic and has high resistant to rust. However, it tends to be less sharp and not at holding its edge, so it's less effective than stainless steel or ceramics blades.

How your knives are stored also has an impact on their sharpness and lifespan, just storing them in a drawer surrounded by other utensils will just leave them to wear, damage and rusting, its practical to store them in knife block (preferably a steel knife block), a magnetic rack (providing that your knives are made of a magnetic material) or knife wallet.